Condeeps. The dinosaurs of the north sea

Norwegian Petroleum Museum, Stavanger (Norway)

When oil was found in water depths larger than 150 meters in the North Sea in the 1970s, a new and revolutionary concept was needed to be able to support deck structures for production of petroleum. Norwegian entrepreneurs introduced a new design based on their experience with large structures of concrete. The design, named Condeep, was developed. For a period of 25 years this design became the dominant support structure for platforms placed in water depths up to 300 meters. By early 1990s new technology had been developed and deeper waters were being challenged. The Condeeps could no longer withstand the competition and the industry had no longer use for the giant structures. However, the world needs a symbol or monument over a very special period that may come to an end sooner than we know. One such platform may be well suited for a UNESCO world heritage – the Draugen platform in the Norwegian Sea. This article introduces the reasoning behind such a suggestion.

When Norway became an oil producing country towards the end of the 1960s, only a few people expected that a Norwegian entrepreneur company could become one of the largest subcontractors to the upcoming exploration of the North Sea – using concrete as a material in exceptional and giant structures.

Realizing what a great influence the oil industry has had for the development of economic and social life in Norway there have been several ideas how to preserve at least one of these structures for the future – when the fossil fuel era comes to an end. One platform - in my mind - Draugen, could be a strong candidate for becoming an international monument and possibly gain status as a UNESCO world heritage status. Having spent more than 30 years in the Norwegian oil industry I have seen most of the technical progress that has been taking place. The most important structures are the huge Condeeps (abbreviated from Concrete Platform for Deep Waters). The time of the fossil fuels may be obsolete within this century, the petroleum industry has been the basis for the development of modern Norway and the concrete structures are unique pieces of design and construction.

Back to topConcrete platforms for the North Sea

The first traces of a material that can have some resemblance to concrete dates back 20 000 years. It was however the Romans, a little more than 2000 years ago, who really developed the knowledge and competence of how to create huge buildings based on using ashes from volcanoes as an important ingredient. The volcano ashes used in concrete were called pozzolans after the city Pozzuoli, close to Naples and Vesuvius, where the material was first collected.1 Two hundred years ago, an industrial product named Portland cement was introduced overtaking the market from the natural pozzolans.2

In Norway concrete has been used as the main material in dams built for producing electricity. Until the mid-1950s concrete was the dominating material and many companies were involved in the big projects in the Norwegian mountains (fig.1).

A few years after oil was found in the Norwegian part of the North Sea, Norwegian Contractors (NC) was formed in 1973 as a Joint Venture of three large contractors and their idea was to utilize their joint experience, competence and resources and take advantage of the country’s special topography with deep fjords and plenty of raw material to produce structures specialized for this new industry.3

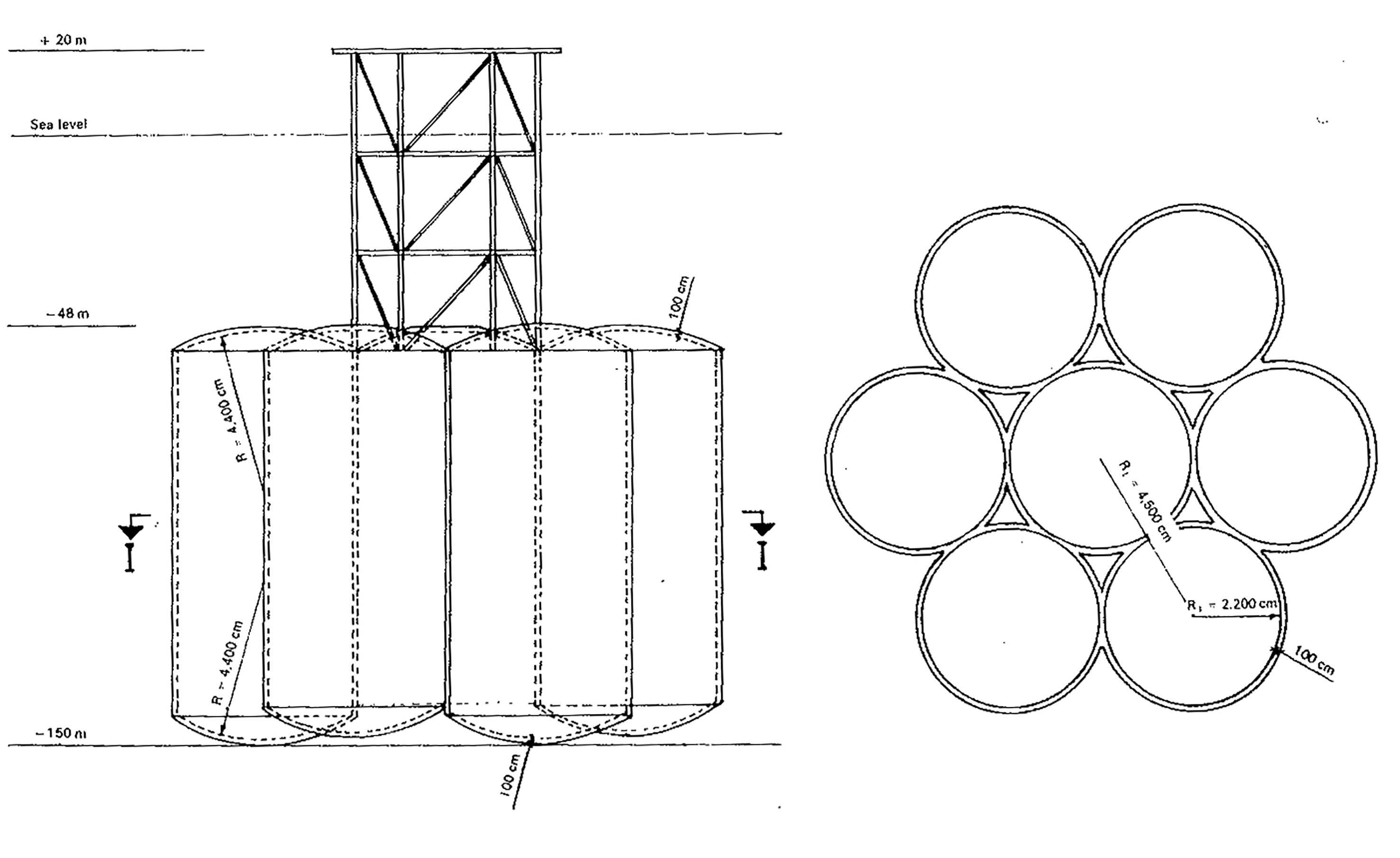

The first ideas using concrete for oil extraction were launched in 1970 by two of the co-founding companies – and a concrete floatable platform support was introduced (picture) shortly after.

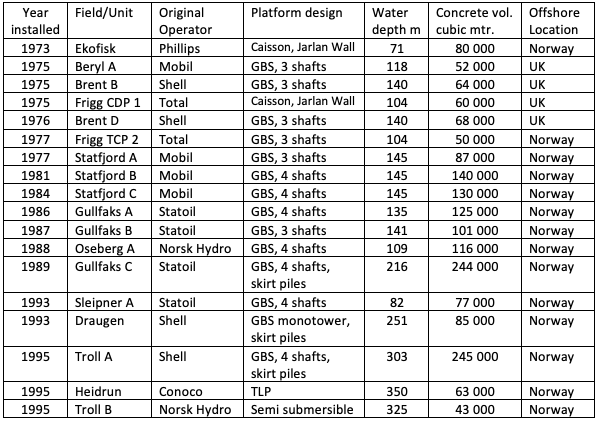

A total of 17 giant structures were built in Norway by Norwegian Contractors (and the founding companies) during a period of 25 years. Most of them were Condeeps based on the principle of standing securely on the sea bed only by the force of its own weight – a so called gravity-based structure (GBS).

Of the listed structures Ekofisk, the Brents and the Friggs have already been decommissioned – but the concrete structures are left in the fields with the deck structures removed (fig. 4).4

The Norwegian Petroleum Museum (NPM) cooperates with The Norwegian Oil and Gas Archives (NOAGA) in documenting many of the large developments on the Norwegian Continental Shelf. So far five large Industrial Heritage Projects have been completed (Ekofisk, Frigg, Statfjord, Valhall and Draugen).

In addition, NOAGA has received the complete archives from Norwegian Contractors for the period between 1973 and 1995 when the company was in existence. Altogether there is 16 shelf meters of interesting material to be found. All films and photos from the building, transport and installations of the concrete platforms have been made available for the NPM. Many of these are made publicly available at the site https://digitaltmuseum.no. – more than 3000 pictures can be found using only Norwegian Contractors as search criterion.

Back to topDesigning Condeeps

From the list above one finds that the Condeeps came in many different shapes both in height and number of legs. Most of them were never meant to be removed, but some are designed for being towed back to the coast to be destructed. The above mentioned Draugen is one of these.

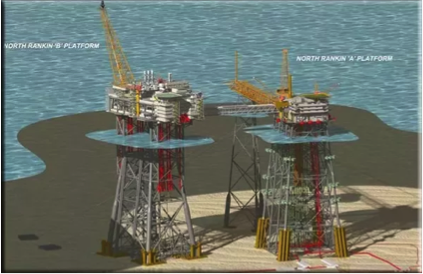

There were several reasons for starting to build concrete platforms in the North Sea. In the early 1970s, several huge discoveries of oil on the British and Norwegian continental shelf, Beryl, Brent, Ninian and Statfjord were made, to name the largest. At that time, there were no marine structures such as “jackets” (large steel framework structures fig. 5) or floaters suitable for building production facilities of 120m - 150m water depth in the North Sea. In addition, there was no infrastructure in the form of pipelines for exporting oil and gas from the platforms.

In the 1960s the Gulf of Mexico was the reference point for offshore oil and gas production. However, there were several conditions that were different in the North Sea. One of these differences was that the production rate was consistently higher from the North Sea areas. This required systems for the UK and the Norwegian sectors with more equipment and considerably increased weight. Steel platforms at that time had to have the deck installed offshore after the support structure was placed on the seabed. Cranes with lifting capacity of 10,000 - 12,000 tons, as we know it today, did not exist then. It was therefore a huge task to transport modules of 800-1000 tons offshore, lift them into place and connect the modules that could weigh a total of 20,000-30,000 tons. Typically, in the Gulf of Mexico, lifts of 500 to 5000 tons were covered. Second, weather conditions which were constantly much worse in the North Sea, even though the Mexican Gulf had its challenges during the hurricane season. Third and last, the generally larger distance to shore resulted in increased demands for logistics arrangements and space for equipment storage on board. The development of offshore platforms in the Gulf of Mexico had started with facilities near shore and pipeline installation became an integral part of field developments. The platforms were connected to the nearest pipeline as one moved further from the coast. In the North Sea, the most promising areas were situated far from the coastline both in the UK and in Norway and there were no pipelines available.

The basic conditions and the marine environment are more demanding in the North Sea. Piling equipment designed for installation of steel platforms in the Gulf of Mexico, was inadequate for the seabed in the northern North Sea with hard sand and clay layers formed by the glaciers during the ice age. Without pipelines for export, oil storage and offshore loading to tankers were necessary to uphold a consistent production under adverse weather conditions. There were thus many challenges and opportunities that the industry faced when developing large oil fields in the North Sea. Norwegian industry, and Norwegian entrepreneurs, were active and inventive in promoting ideas and developing suggestions for new concepts. Høyer-Ellefsen and Akergruppen (two of the companies forming Norwegian Contractors in 1973) were involved in a collaboration that proved to be very successful resulting in the Condeep platform design. The biggest challenge was with the oil companies that had to choose solutions and methods that neither supplier nor customer had full scale experience with.

The reasons for the operating companies Mobil and Shell in 1973 to develop the Beryl and Brent oilfields on the UK shelf, using concrete platforms were to avoid the expensive and time-consuming work of installing piles to secure the steel jacket. In addition, the platform had sufficient buoyancy to carry the deck with the necessary facilities for processing the petroleum from an inshore construction site. Thus, the deck could be equipped and coupled up in a controlled environment and the finishing offshore was substantially simplified. And last but not least, when the platform was set on the seabed it no longer needed buoyancy and the cavity in the concrete platform would serve as oil storage (fig. 6).

The first three Condeeps were delivered to Mobil and Shell in 1975 for the British continental shelf. It also meant the start of an industrial adventure for Norwegian suppliers. The concrete substructures were built in Norway and the deep fjords on the west coast were suitable for mating with the deck and tow. This gave Norwegian shipyards a natural advantage for building top sides. The effects of this scheme were huge. Engineering companies, technology development, subcontractors, consultants and research institutions were engaged because the business was conducted in Norway. If Mobil and Shell had focused on steel platforms for Beryl and Brent, construction work would not have ended in Norway and Norwegian industry would not have had the same development opportunities. When Mobil found the Statfjord field in 1974, they were building the Beryl platform and they chose the same solution for the Statfjord development.

The Ekofisk tank was the first of the giant concrete structures to be placed on the seabed of the Norwegian Continental shelf. It was not a Condeep, but it made it possible to establish a company and a construction yard for future oil related activities. The two Norwegian entrepreneur companies Ingeniør F. Selmer A/S and A/S Høyer-Ellefsen were contracted by the French company C.G. Doris in May 1971 to build an ‘oil container of concrete’ that could hold one million barrels of crude oil.5 Two years and one month later the structure now known as the Ekofisk tank was towed to the oil field.6 Within that time span the companies also had to develop a site that should be the breeding ground for the Norwegian concrete dinosaurs for more than 20 years.

The next month (July 13, 1973) the first contract for the new concept of an oil platform (Condeep) made of concrete was signed.7 It was Mobil North Sea Limited who wanted to use this type of platform for their Beryl field development. Two weeks later Shell ordered a similar platform for their Brent field development also in the UK sector of the North Sea. The Beryl and Brent platforms were built in Stavanger and have been operating on the British side of the border. Brent B was abandoned in 2016 and the decommissioning started early in 2017. The Beryl platform is still operating.

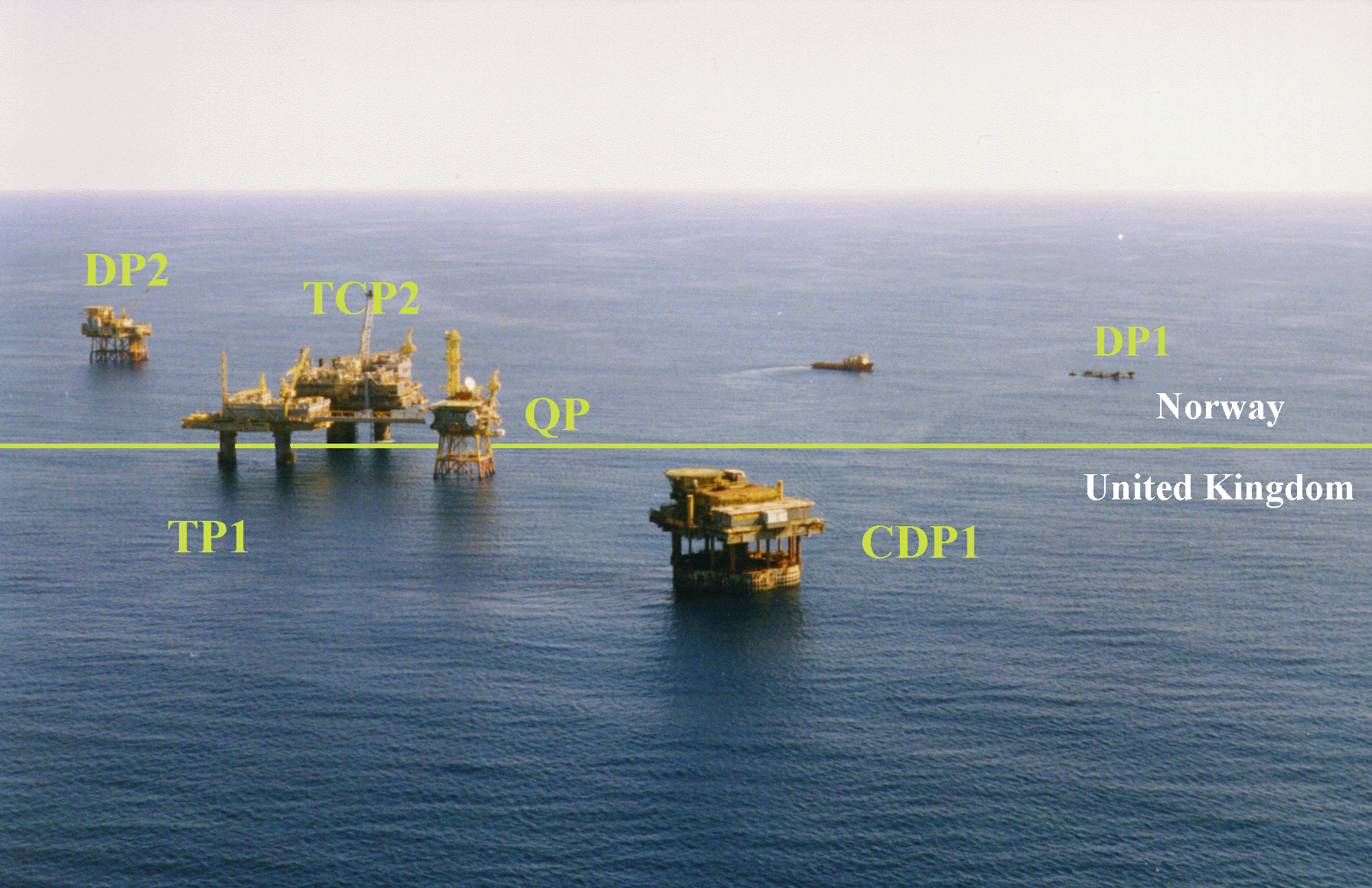

The next field to be using concrete platforms was the French operated Frigg field where the gas reservoir stretched out to both sides of the British/Norwegian border. The treatment platform TP1 was designed by Sea Tank Company in Paris and was built in Scotland, The Manifold Compression Platform MCP-01, designed by Doris Engineering was built in Sweden. This platform was decommissioned in 2006. Two Frigg platforms were the only concrete platforms to be built in Åndalsnes and only one was of the Condeep-design, The Treatment Compression Platform 2 - TCP2. The TP1 and the TCP2 were physically connected with a bridge crossing the Norwegian UK border (fig. 7).

The three platforms for the Statfjord field, all Condeeps, have been operating in one of the world’s largest offshore oil fields since 1979. On October 12th, 1983 they produced a record volume of 870 000 barrels of oil. Based on the present oil price of 50 - 60 USD per barrel, that means roughly 2 million dollars per hour!

The Gullfaks A was the first platform to be 100% Norwegian owned and operated.8 The Gullfaks offshore field was owned jointly by the three Norwegian oil companies that existed at that time. Statoil was the operator with Norsk Hydro and Saga as partners. The field has used three Condeep platforms for the development and the Gullfaks C was the first platform to be fitted with concrete skirts (to penetrate the sea bottom to create a stable foundation), and it is also the heaviest structure to be moved by man (1,5 million metric tons).

The Sleipner A platform was the only platform to collapse during construction. On a beautiful August morning in 1991 the concrete structure sank during a submergence test In the Gandsfjord close to Stavanger. One of the internal cells could not withstand the pressure from being submerged lower than the depth at the destination in the North Sea and water poured in. On the way down to the bottom of the fjord the structure imploded creating a soundwave that was registered as a small earthquake at a geological center in Bergen, several kilometers away.9

The Draugen was built with only one leg – a monotower design. The platform and its designer Olav Olsen were in 1995 awarded the Gustave Magnel Golden medal for a structure in prestressed concrete.10 The platform was the first to produce oil north of the 62nd latitude and the only platform north of this borderline to be standing directly on the sea bottom. The other platforms are floating structures either semi-submersible structures (fig. 8) or ships (fig. 9).

The Troll A – the tallest structure to be moved by mankind 472 meters from the lowest point on the concrete skirts to the top of flare boom It was also the last of the giants to be built for the North Sea (fig. 10).

When it was placed on the sea bottom at a depth of more than 300 meters in 1995 it meant the end of an era. Similar structures have been used for the oil industry in other parts of the world such as east of Canada (Hibernia and Hebron) and offshore the Pacific coast of Russia (Sakhalin). The Condeeps are fantastic structures that not only were meant to support the oil factories, but also to offer temporary storage for the black gold.

Back to topPreserving one of the dinosaurs of the North Sea: why and how

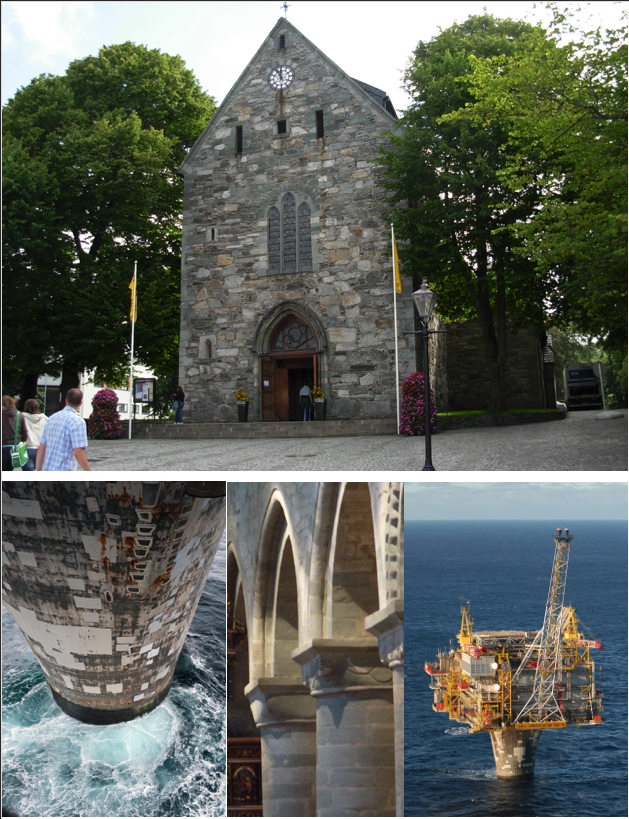

In his book Leviathan (1979), Alfred Hauge used the words "Condeep Cathedral" and “petrodome” to describe the shape of these giant structures and one can sense some resemblance with cathedrals. Hauge’s fascination with these structures was also present in an essay from 1980: "So beautiful it is with the tall slender shafts as they are called; resembling huge lighthouses. I will not be surprised if such structures will inspire architects to create new ideas for example churches …"11

Even the interior of the Troll A platform lends itself to giving an impression of a large church. Picture to the left is from a concert given in 2006 by the song artist Katie Melua at the bottom of the Troll A platform (the deepest concert ever held).12 But not only inside – the top of the platform Draugen as it can be seen above the water does seem to copy the Stavanger Cathedral from the 12th century – both internally and externally.

Should we preserve one of the dinosaurs for eternity? – It is technically possible but extremely expensive! Indications that have been discussed among experts, range between 1 to 3 billion American dollars, only for ‘picking it up’ offshore, transporting and placing it close to shore. What it will cost to prepare it and presenting it as an industrial heritage has not been evaluated. But as a monument of the era that brought Norway immense wealth in money and technological competence it should be an idea to follow up at least.

The importance of these structures for the development of deep-sea oil producing technology and the growth of Norway’s and other oil producing nations’ position today cannot however be underestimated. It is therefore relevant to ask if one of these giant structures should be preserved for future generations and be used as an arena to explain to the general public all the technical aspects of deep-sea natural exploitation.

UNESCO World Heritage Sites is a program under the auspices of UNESCO for the preservation of a variety of natural and cultural sites on Earth. The places, such as a forest, a mountain, a lake, a desert, a monument, a building, a complex, or a city, are selected because of their cultural importance or for the natural history of humanity. UNESCO's World Heritage List is the most widely used environmental treaty in the world. The program was launched on November 16, 1972, when UNESCO adopted a Convention for the Protection of Cultural and Natural Heritage. 1092 places were listed on March 2019, 845 of which are cultural heritage sites, 209 natural heritage sites and 38 a mixture of the two categories.13

Industrial cultural monuments are part of the cultural heritage sites but represent only about 5% of these. Requirements for world heritage status are:

- Outstanding universal value. An area or object has outstanding universal value if it represents in the global context the best example within a cultural or natural subject of a particular format.

- Integrity. All world heritage objects or areas must contain all elements necessary to express the prominent universal values. The area's integrity is also dependent on the delimitation capturing all necessary elements.

- Authenticity. The object or the environment's degree of origin or authenticity is an expression of authenticity.

- Protection and management. World Heritage Sites should be subject to long-term formal or contractual protection against measures or threats that may adversely affect the universal values.

- The areas must be clearly defined and where necessary be surrounded by a buffer zone with its own provisions ensuring that qualities within the world heritage area are not adversely affected.

- The management of the area will follow a reversal plan that ensures coordinated follow-up of measures that are best for the area.

- Human activity within world heritage sites must be ecologically and culturally sustainable.

- Local support. A world heritage nomination will not be approved without it being anchored in the community.

Why an oil platform? Through more than fifty years of activity on the Norwegian continental shelf (NCS), the petroleum industry has grown to become Norway's most important industry. The exploration and production of oil and gas has been the most important reason for the global development of modern society for more than 150 years.

In Norway the industry directly and indirectly employs around 300,000 people, while a high tax rate and the state's direct ownership contribute to the bulk of the value creation on NCS. Many of the contracts for building modules and production units for the Norwegian Continental Shelf have been and still are being placed all around the globe. Of the gross domestic product in Norway in 2014, the state calculated that it amounted to NOK 958.9 billion. That is about one third of the 3 167 billion that are created in Norway for a year. It includes both oil and gas production, investments on platforms and ships, as well as all those working on petroleum.

In April 2001, the Directorate for Cultural Heritage of Norway expressed in a letter to the Norwegian Petroleum Museum the following: “The Directorate [..] will like the oil museum to draw up a systematic overview of large physical oil installations that may be preserved - on the spot, at museums or elsewhere.” So far the phrase "large structures" has meant equipment limited by size and weight up to 10 meters and/or 100 tons. An oil platform is of a completely different magnitude. But on the other hand – no suggestions have ever been officially introduced – maybe it’s about time!

Why Draugen? The most unique feature from the Norwegian oil industry is the use of concrete platforms – Concrete Deepwater Structures, Condeep. The Draugen is a concrete platform and has also achieved an international award for its design – The Golden Medal Gustav Magnel 1989 - 1994. Concrete technology that has been developed is also applicable to other geographic areas. Draugen was the first platform north of 62th latitude – an important limit politically. Indeed, the Norwegian oil industry's expansion towards the north has contributed to the most polarized conflict line in Norwegian oil policy. At the end of the 1970s, the battle was about whether to open the areas north of 62nd latitude for oil drilling. From the 1970s, the opposition was primarily between fisheries and conservation interests on the one hand and industrial interests and a desire for local business development on the other.

Draugen is one of the fields that has the highest utilization rate on the Norwegian continental shelf (about 70%) - which is world-wide super league. The Draugen will probably shut down production from the main reservoir within 10 years. The unique monotower structure was also designed to be physically removed from the seabed in one piece. Basically, all installations on the field shall be removed when production ends.

Save Draugen! There is no project launched to save the platform for eternity. The Draugen field is still producing at a daily rate of about 20 000 barrels a day. The planning for abandonment has not officially started - yet. When I (as a private person) have introduced the idea to different persons and authorities, they have all shaken their heads and called it crazy and impossible. However, after having presented my case, the skepticism has often turned into curiosity and sometimes excitement. It all started during an informal dinner meeting with representatives of the Directorate for Cultural Heritage of Norway. I started to investigate what were the rules and regulations for the UNESCO-list, and I discovered that it could be possible if one could get enough attention. I made a PowerPoint presentation and showed it to friends and historians. They were all very skeptical of the project, but since I am an engineer by profession, I explained the technology behind the idea (not thinking about the money) and they were convinced by the project… One person said after having seen and heard my enthusiastic dream: It may be a dream – but the idea is crazy enough to actually be possible!

That has since been my guideline and I will spend my first year in retirement following my dream! The seeds have been planted, but it still is a long way to go. The cost will be enormous and many technical problems will have to be solved – but 60 years ago nobody believed there was any oil at all in Norwegian waters…

Links:

http://www.norskolje.museum.no/en/home/oil-facts/publications/oil-and-gas-fields-in-norway/

http://www.kulturminne-ekofisk.no/

http://www.kulturminne-frigg.no/

http://www.kulturminne-statfjord.no/

http://www.kulturminne-valhall.no/

https://draugen.industriminne.no/en/home/

- 1. Ruth Whitehouse, John Wilkins, The Making of Civilization. History Discovered Through Archaeology (New York: Alfred A. Knopf, 1986).

- 2. Frederick Measham Lea, The Chemistry of Cement and Concrete 3rd ed. (London: Arnold, 1970).

- 3. Øyvind Steen, På dypt vann. Norwegian Contractors 1973 – 1993 (Oslo : Norwegian Contractors, 1993), 16.

- 4. Adam Vaughan, “Shell begins huge task of decommissioning Brent oil rigs”, The Guardian, 06/02/2017. Url : https://www.theguardian.com/business/2017/feb/06/shell-decommissioning-… (accessed 17/05/2019).

- 5. Steen, På dypt vann (cf. note 3).

- 6. Ibid.

- 7. Ibid.

- 8. Harald Tønnesen, Gunleiv Hadland, Oil and Gas Fields in Norway. Industrial Heritage Plan (Stavanger: Norwegian Petroleum Museum, 2011).

- 9. "Havariet av SLEIPNER A GBS, August 1991", Presentation at the Petroleum Safety Authority Norway conference (PTIL) 2007.

- 10. The letter from AIG-Stiching declaring the winner was sent September 7th 1994 – the ceremony was held in 1995. See : https://draugen.industriminne.no/en/2018/05/14/medal-award-for-draugen-…

- 11. Alfred Hauge, Leviathan (Oslo: Gyldendal Norsk Forlag, 1979).

- 12. Trailer here: https://www.youtube.com/watch?v=o5Wrk7GRiS4 (accessed 29 May 2019)

- 13. UNESCO World Heritage. Url: https://whc.unesco.org/en/list/ (accessed 02/04/2019)

Hauge Alfred, Leviathan (Oslo: Gyldendal Norsk Forlag, 1979).

Measham Lea Frederick, The Chemistry of Cement and Concrete 3rd ed. (London: Arnold, 1970).

Steen Øyvind, På dypt vann. Norwegian Contractors 1973 – 1993 (Oslo : Norwegian Contractors, 1993),

Tønnesen Harald, Hadland Gunleiv, Oil and Gas Fields in Norway. Industrial Heritage Plan (Stavanger: Norwegian Petroleum Museum, 2011).

Vaughan Adam, “Shell begins huge task of decommissioning Brent oil rigs”, The Guardian, 06/02/2017.

Whitehouse Ruth, Wilkins John, The Making of Civilization. History Discovered Through Archaeology (New York: Alfred A. Knopf, 1986).