The energy transition in the Swedish iron and steel sector, 1800 – 1939

Department of Economic History, Lund University, Sweden

cristian.ducoing@ekh.lu.se

Unit of Economic History, Umeå University, Sweden

fredrik.olsson-spjut@umu.se

Cet article analyse la transition énergétique du secteur sidérurgique suédois, entre 1800 et 1939. Leader dans le contexte européen au 19e et 20e siècles, l’industrie sidérurgique suédoise est un cas intéressant à analyser au prisme de la transition énergétique et de la composition et de l’évolution du stock de capital (classées par technologie énergétique). Une étude approfondie de l’évolution du stock de capital dans le secteur permet en effet d’étudier la dynamique à l’oeuvre. En mettant l’accent sur les phénomènes d’adoption de la technologie, d’infrastructure carbone verrouillée et de transition énergétique, elle représente un bon moyen de comprendre les difficultés actuelles à aller vers des sources et infrastructures d’énergie plus propres.

Introduction

Energy transitions are one of the most interesting phenomena of the present and past. The effects of C02 emissions on our climate are so massive that the age in which we are living is now known as the Anthropocene. One of the main challenges of this geological epoch lies in combining economic growth with reduced emissions. What could we learn from the past in order to face these challenges? Energy transitions in specific sectors are relevant starting points from which to gain useful insights.

Iron and steel have been major actors in the Swedish economy. Since the 18th century, Sweden consolidated itself as the major actor in the European iron market, and the reconstruction of trade under the British Industrial revolution demonstrated the importance of Swedish iron ore to the growth and diffusion of the industry.1 But an overlooked aspect of the Swedish iron trade, despite its historical prominence in the country’s economy, has been the internal energy transition and how coal and charcoal prices influenced the industry’s progress (and decline) throughout the 19th and 20th centuries. Moreover, and from an international perspective, the iron and steel industry have several unique characteristics, such as the energy carriers used in production, (charcoal, coal, electricity), the enormous fixed investment costs involved in establishing a furnace, the backward and forward linkages, and their leading role in the first and second industrial revolutions. Previous research on changes in the Swedish energy system has focused primarily on the political and the national levels, and, alternately, on how different types of energy developed and evolved during the twentieth century. In the Swedish case, for obvious reasons, the expansion of hydropower has been an important research area, and so too has the growth of fossil fuels as a share of Sweden’s total energy consumption from the end of the 19th century.2 In this context, the present study makes a contribution as an in-depth analysis of energy transition at industry level.

A striking feature of the Swedish iron industry is that it did not switch to coal in the 1800s, unlike England/Wales, France, and Germany.3 Instead, the business underwent a technical change within the confines of charcoal-based production.4 From the 1850s onwards, capital investments in iron and steel were targeted at energy efficiency in furnaces and new steel-making methods.5 Larger units and more efficient methods decreased the amount of charcoal required per ton of iron and steel produced, but the total energy consumed by the sector still increased during the late 19th and early 20th centuries.6 These developments are intrinsically linked to the debate on the underlying causes of Industrial Revolution, framed by the theory of the high wage economy and the capital–labour ratio. In the case of England, high wages plus cheap energy made the incentives to invest in capital-saving labour. Using this framework to analyse the Swedish iron and steel industry with the aim of understanding the causes of the energy transitions therein, we first need to account for the price structure of the energy carriers and the final price paid per horsepower unit. Accordingly, the aim of this article is to unpack the reasons behind these energy transitions and how path dependence, natural resources endowment, price structure, and policy are interlinked to generate this output. Why was the energy transition in the Swedish iron sector delayed? What were the main factors behind this delay? Why was charcoal so competitive for so many years? Was the previous investment related to natural resource endowments or policy?

To address these questions, the present study draws on new data on industrial energy consumption, qualitative sources on the problems faced by the industry in the interwar period, and previous literature. The article is organised as follows: section two presents the historical development of the Swedish iron and steel industry. Section three shows the main changes in the energy matrix in the iron and steel sector. Section four concludes.

Back to topHistorical development of the Swedish iron and steel sector 1800-1939

Swedish iron and steel 1800-1939: General development of production and competitiveness

The iron industry in Sweden dates back to the Middle Ages and has been a major part of the Swedish economy since the 15th century.7 It is well known that the industry consumed large amounts of charcoal (wood).8 Then as now, Sweden was sparsely populated, with relatively large woodlands and substantial deposits of high-quality iron ore. This drove the competitiveness of the Swedish iron producers, especially during the period leading up to the breakthrough of coal-based iron production in England and Wales. Sweden was Europe’s leading iron exporter from the latter part of the 17th century to the middle of the 1800s, when it shared the top position with Russia.9 Around the turn of the 18th century the international iron market underwent a rapid and radical change with the advent of the puddling process in England and Wales, when coal became the primary source of energy for local iron production.10 From the Swedish perspective, the international changes of technology and the British energy transition during the Industrial Revolution lent new impetus to the production and exportation of iron and steel. Shifting European demand for Swedish iron prompted two fundamental change processes in the county’s output during the 19th and the early 20th centuries.

First, the industry became more oriented towards higher quality products; that is, it was forced to abandon the strategy of ‘bulk-oriented’ production of bar iron and focus on meeting the new demand for high-quality iron, and later steel, that sprang from industrialisation and emerging manufacturing activity in other countries. With regard to the shifting demand for Swedish iron ore, the European, and especially the British, appetite for the metal decreased significantly during the 19th and early 20th centuries. However, Sweden’s dwindling competitiveness on the European iron markets was largely offset by rising demand for its iron and steel from the USA.

Second, the changing international markets resulted in streamlining and specialisation within the Swedish iron and steel industry. As we have seen, these processes necessitated larger but fewer units of iron production and targeted energy efficiency via furnaces and new steelmaking methods. These bigger production units and new methods decreased the amount of charcoal called for per ton of iron and steel produced, yet the sector’s total energy consumption increased all the same during the late 1900s and into 20th century. Known as the first ‘death of the ironworks’ in Sweden, the period 1850–1890 was marked by the closure of several production units and their replacement by new charcoal-fuelled iron and steel plants that had energy, geographical, or logistical advantages.11 These developments did not slow the general trend of stronger international competition and decreasing margins within the Swedish iron and steel industry, however. Then, during the 1920s and 1930s, falling international competitiveness led to Sweden’s second ‘death of the ironworks’. Previous research has shown that 72 ironworks closed down during this period. In the interwar period, the Swedish iron and steel industry underwent an energy transition from charcoal to coal, to be followed later in the 20th century with the addition of electricity to them mix.12

Sticking to charcoal during the 19th century

Sweden has a near-complete absence of domestic coal reserves. Hence, the country was unable to transform its energy system, from wood to coal, without foreign trade; this is part of the reason why, as we have noted, the Swedish iron industry did not change to coal in the 1800s. Instead, the industry introduced technical changes to its model of charcoal-based production.13 The capital investments in the iron and steel industry targeted energy efficiency in furnaces and new steel making methods, especially from the 1850s and onwards.14 Relatively larger units and more efficient methods did decrease the amount charcoal per produced ton of iron and steel, but the total energy consumed by the sector increased during the latter half of the 19th century and the first decades of the 20th century.15 With the price of charcoal increasing vis-a-vis coal during this period,16 Sweden’s iron and steel industry bore the brunt of stronger international competition and diminishing margins. International developments in the iron and steel industry during the 19th century played a major role in the streamlining processes deployed in the traditional iron industry. Another major issue in the Swedish iron industry was the cost of energy before the coal-based technological breakthrough in England and Wales. The rising relative prices of charcoal during the 1800s compounded this situation, and the industry in Sweden responded with capital investments in new plants and the usage of new methods of production.

Previous research on charcoal consumption in the iron industry has put charcoal consumption per ton of bar iron at 417 hectolitres (hl) in 1825. This figure also includes the charcoal consumed the manufacturing of pig iron.17 But as the century wore on, charcoal consumption per ton bar iron was reduced by major new technological applications (see Figure 4), such as the Bessemer and Martin processes. By the start of the 20th century, new investments had reduced fuel requirements to 129 hl of charcoal per ton bar iron.18 Looking as far back as 1700, calculations and fuel intensity point to an approximate energy consumption of 525 hl of charcoal per ton.19 The technological development of and investments in new furnaces and methods is one important factor in how and why the Swedish iron and steel industry did not change its main energy carrier during the 19th century. Another significant factor in why the industry did not undergo an energy transition is the historical institutional context within Sweden and its iron industry; strict regulations were introduced from the 1630s, perhaps because of high energy consumption. Apart from being part of the mercantilist model of the era, these regulations also facilitated management of the country’s strategically important forests.

Stringent regulations and controls on Swedish iron production were formally introduced in 1637, with the establishment of the Bergskollegium (Board of Mines). From the 1740s the regulations were tightened further, with restrictions placed on total output per ironworks. The regulations also governed site locations, as well as privileges such as local precedence to needed forest and taxation of those living within the geographical boundaries of the ironworks.20 These Crown interventions have been debated within the Swedish literature on iron production, giving rise to two hypotheses about the restrictions on output per year/ironworks. First, Heckscher has suggested that the regulations were aimed at increasing the price of bar iron on the international market. This theory is based on the author’s view that the Crown wished to exploit the monopolistic position of Swedish iron in the 18th century.21 Hildebrand, on the other hand, puts forward a different argument: that new regulations from the 1740s onwards were the result of increasing local de-forestation around the ironworks. In this interpretation, the Crown’s aim was to curtail the massive and growing output of the traditional iron region of central Sweden and thus decentralise production.22

The debate is still ongoing. However, estimations of total output show that central Sweden’s production stagnated and nearly stalled in the mid-18th century. This finding, combined with other evidence of geographical decentralisation during the 1800s, appear to lend credence to the hypothesis ventured by Hildebrand and others.23 The regulations began to be loosened in the first half of the 19th century, and in the second half the liberalisation process was completed; for example, the Bergskollegium was dismantled in 1857.24 Thus, the institutional context hampered the overall exports and production of the Swedish iron industry until the 1850s.

As the traditional energy carrier, charcoal played a major part in the industry and the old institutions that governed it. Technological changes, capital investments, and product specialisation within the wood-based energy system, together with deep-rooted institutional developments, can be seen as explanations as to why Swedish iron and steel stuck to charcoal during the 1800s. More specifically, traditional location patterns, historical regulations on charcoal production, and the absence of major coal deposits within Sweden played a vital role in the industry’s choice to focus on charcoal as the major energy source until the early 20th century.

The transition away from charcoal as the preferred choice of energy began during the 1920s and 1930s, when the Swedish iron and steel industry switched to a mix of electricity and coal-based production (but with the latter initially used in greater proportions). The pace of this shift to a new form of energy has been attributed by previous research to the crises that the industry experienced in the 1920s. After WWI, the prices of imported iron and steel fell sharply, and the prices of regionally produced charcoal increased. This situation led a structural change within industry. Seventy-two ironworks closed during the interwar period, an absolute majority of which were charcoaled based.25 But although the general developments and structural changes within Swedish iron and steel during the 1920s and 1930s have been quite well documented, the relatively rapid energy transition – and the dynamics related to this process – have not been analysed in the same extent.

Back to topChanges in the mix of energy carriers in the Swedish iron and steel industry

Sweden lagged behind other western European nations in the transition from wood to coal during the 19th century – a key marker of national industrialisation. One can argue that Sweden’s industrial breakthrough came relatively late in relation to those countries that witnessed the First Industrial Revolution in the late 18th and early 19th centuries, and that this affected the timing of the energy transition. On the other hand, the literature has shown that coal played an important role in Swedish industrialisation from the 1870s onwards, but that the bulk of the industry’s energy consumption consisted of bio-energy up to the end of the 19th century. The explanation for this is found largely in the non-existent energy transition undergone by the steel and iron industry – the largest energy consumer within the Swedish manufacturing sector – over the period. Lindmark and Olsson-Spjut argue that coal, from the 1870s, was vital to the development of transportation (railroads) and to the mechanisation (steam-engines) of manufacturing. A consequence of this development was that coal became a prerequisite for the utilisation of bioenergy in remote parts of the country that were hard to access with traditional transportation and mechanisation. But analysis of the energy used for producing iron and steel in Sweden, and of the aggregate numbers for different energy carriers, shows that the industry did not switch from charcoal-based to coal-based production during the 19th century.26 This is a major part of the explanation for why Sweden’s industrial breakthrough can be seen as industrialisation within a bio-energy framework. The findings of Lindmark and Olsson-Spjut show that this can be debated in consideration of the dynamics of energy consumption.

During the 1910s, Swedish pig-iron production started to make use of coke to fuel its furnaces. Up until the end of WWI, coal-based production constituted a small fraction of total pig-iron production in the country. But during the interwar period, the iron and steel industry came to regard this substance as its preferred energy carrier. Coke-based pig iron production started to increase during the 1920s, and the following decade this carrier accounted for half of Sweden’s total pig iron output (charcoal accounted for the other half). This dynamic changed during WWII, which hit coal and coke imports. After the war the clear trend of energy transition to coal continued, which rapidly decreased charcoal-based production. The energy transition within the industry also included, to a lesser but steadily increasing extent, electrical-based production.27

Energy transition during the interwar period

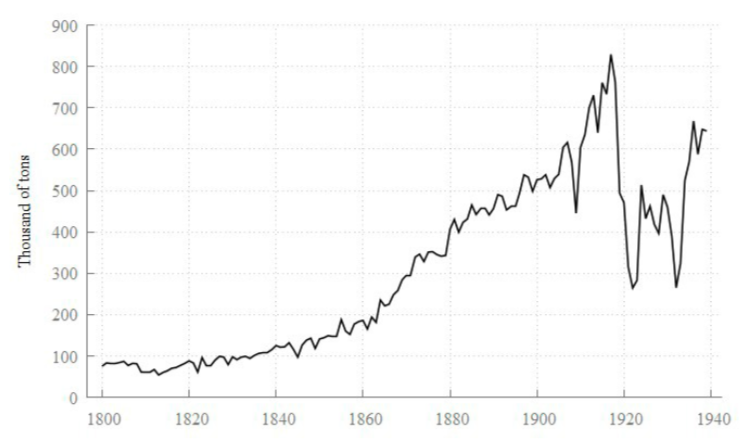

The energy transition in the Swedish iron and steel trade during the interwar period came as part of, but also as a result of, major changes in national and international production and demand for iron and steel. In 1921–1922 the Swedish economy experienced a deflation crisis, and labour-market conflict brought the iron and steel industry to a complete halt for six months in 1923. This can be seen in Figure 1, which shows total iron output over the period 1800–1939. In other words, the 1920s marked a period of stagnation in the iron and steel industry. This phenomenon was also a result of changes to national and international demand for both metals. This is especially salient in the case of pig-iron production; international demand for Sweden’s high-quality pig iron (that is, containing low levels of sulphur and phosphorus) decreased during the 1920s with the emergence of new steelmaking processes capable of using lower-quality forms. To an even greater extent, Swedish pig-iron production was affected by changing local demand. New production technologies implemented in Sweden’s iron and steel industry – such as production of ingot iron, which used scrap metal as its main input – became an alternative to pig iron and caused a fall in demand for the latter.28

Sources:1800- 1913: Lindmark & Olsson (2018), 1914–1939 SOS (Swedish Official Statistics), Bergshandteringen (Mining industry).

Table 1 shows the development of energy carriers utilised in the Swedish iron and steel sector during the period 1800–1939. The analyse is based on petajoules (PJ), which enables a comparison of energy consumption between wood and coal/coke. Until the end of WWI, charcoal dominated the energy consumption. The Swedish iron and steel industry had started to make limited use of coal around 1910, but the energy transition really gathered momentum in the 1920s. By 1939, 67 percent of energy consumption was derived from fossil fuels (coal and coke).

The changing demand structure led to a decrease in numbers of iron furnaces – that is, the above-mentioned ‘second death of the ironworks’. Increasing volumes of imported pig iron during the interwar period is also an important factor in the structural changes to the Swedish iron and steel sector. Stronger international competition put pressure on the Swedish industry to lower production costs in the industry. In the case of iron production, the first step was to invest in new coke-based production processes. When it came to high-end steel production, the interwar period encompassed the development of electro-steel production, which began to take off during the 1920s. At the start of that decade, this form of production represented three percent of the total ingot-iron production, rising to sixteen percent by 1929. The electro-steel process was one way of substituting imported coal and coke with hydro-electricity.29 As a result, a coal/coke and hydro-electricity mix became the new, established energy system in the Swedish iron and steel industry after WWII, following a transition period between the wars. This development also explains the increase in iron and steel production during the 1930s (see figures 1 and 2).

National demand for forestry and the Swedish iron and steel industry as a strategic industry

The structural change to the iron and steel industry in Sweden during the 1920s and 1930s is quite well documented in previous research,30 which shows the decline of traditional charcoal-based production and the growth of investment in larger coal/coke-based production units. In this context, it is worth considering the dynamics of the industry when it came to the change of energy system in the 1920s and 1930s; that is, why did the industry only undergo an energy transition during this period, when coal had been an option on the international stage for more than one hundred years? One way to deepen our understanding of the energy transition is to make use of qualitive data from the historical period. During the problematic interwar period, the Swedish government and the industry itself conducted investigations into the situation facing the latter. For instance, one study, which concluded in 1927, was led by a committee of experts from government bodies, the Jernkontoret (the iron and steel producers’ association), and economists. The Jernkontoret had initiated the specific investigation with calls for increased import tariffs on iron and an export ban on scrap iron. This association argued that the industry could not cope with ‘unfair’ competition from European iron producers, which were ‘dumping’ iron onto the Swedish market.31 In the event the investigation led to the desired export ban on scrap iron, starting in September 1927.32 On the question of increasing tariffs, the committee was not able to reach a consensus. The government and the influential economists who were consulted – Gustaf Cassel, Eli Heckscher, and Bertil Ohlin – argued that increased tariffs would harm the industry in the long run; they thought that higher tariffs would inhibit the structural changes and the streamlining that the industry needed. As an example of streamlining, they cited the need to increase the production of higher-quality iron at the expense of commercial iron. However, the work of the committee did not result in increased tariffs on iron.33 On the question of tariffs, the economists shared the view that tariffs would jeopardise the industry in the long-run; as an alternative, they all argued for investments in new technologies and larger production units.34 The historical documents on the committee’s work give us insights into the key considerations presented and targeted with regard to the problems in the Swedish iron and steel industry from 1900 until 1927. This period marks the start of the energy transition in the Swedish iron and steel industry, and the archival materials show that the committee was quite unambiguous about what it saw as the major problem facing the industry. Together, the investigations compared the cost of production of Swedish charcoal-based iron with that of European coke-based iron, and the results were clear. Although fuel efficiency had increased tremendously from the second half of the 19th century, in the 1920s the Swedish industry could not match the cost of production of European coke-based iron and steel. This can be explained by two general factors: external and internal competition, and the development of relative prices. With regard to external competition, the committee’s investigation concludes that the international market had lower iron prices than the Swedish market; that is, Swedish iron producers had problems competing on the market for commercial iron. The internal explanations also revolve around the relative price of charcoal in Sweden, which had risen during the second part of the 19th century for two main reasons. First, new and increasing competition from the paper and pulp industry, which preferred the same types of wood as did charcoal production. This pushed charcoal production further north, which resulted in higher transport coast for the charcoal. Second, charcoal production experienced increased labour costs as part of general industrialisation in Sweden and higher demand for labour in the charcoal-producing regions. The investigations also pointed to the newly regulated eight-hour workday as an explanation for increasing labour costs in charcoal production.35

The relative price of charcoal would appear to be the most important explanation for why the Swedish iron and steel industry underwent an energy transition starting in in the 1920s (see figures 4 and 5). The decreasing trend between coal and charcoal prices was around 1.78% per year, with the result that at the beginning of the 19th century, a megajoule of coal was between forty and fifty percent the value of the same unit of charcoal. However, this comparison does not take into account the value of capital stock, a major financial issue for business. But the decreasing trend in coal prices was not enough to promote energy transition in the sector, delaying the change of energy carriers until the 1920s (See Figure 3 and Table 1).

Back to topConclusion and discussion

What can we learn from the energy transition in the Swedish iron and steel industry? First of all, that prices matters. The relationship between charcoal and coal prices was a strong incentive to keep the energy sources in the sector. Moreover, the past investments in charcoal technologies were so important that the comparatively cheaper coal did not match the total cost of charcoal as an energy carrier. We have to wait until the 1920s to see a major shift from charcoal to coal and hydroelectricity, due the technological change in the industry and its difficulties in keeping pace with the world market. Second, the charcoal endowments could be a relevant indicator of path dependence in the industry, bearing in mind Sweden’s history of iron production and ongoing regional specialisation. The seemingly abundant organic resources kept the iron and steel industry with the same energy carriers for a long time.. Finally, the institutional framework is another noteworthy factor. The prohibition on exporting iron ore, in order to promote the national industry by lowering prices and incentivising value added in the industry, was a key factor in understanding the prevalence of charcoal.

There are several lessons from the past that can be useful for our current challenges. New technologies in a given sector are not enough to promote changes, because past investments and price factor structures are the main elements in structural changes to energy systems. At this point, policy enters. Without exogenous incentives, economies could be tempted to keep their current energy system, developing lock-in technologies; but this is a luxury that we cannot afford. The institutional framework becomes crucial in the challenge to achieve lower-emission economic growth through clean energy systems. As an example, falling prices in fossil fuels could provide an incentive for maintaining the combustion engine as-well as coal- and oil-powered heating systems. If there are no policies oriented towards reducing fossil fuel consumption, even with lower energy prices in renewables, the change to clean energy sources could take longer than we expect—causing histories such as that of the Swedish iron and steel industry to repeat themselves.

- 1. Bob Allen, “International competition in iron and steel, 1850–1913”, The Journal of Economic History, vol. 39, n°4, 1979, 911-937; Bob Allen, “Technology and the great divergence: Global economic development since 1820”, Explorations in Economic History, vol. 49, n°1, 2012, 1-16 ; Magnus Lindmark and Fredrik Olsson-Spjut, “From organic to fossil and in-between: new estimates of energy consumption in the Swedish manufacturing industry during 1800–1913”, Scandinavian Economic History Review, vol. 66, n°1, 2018, 18-33.

- 2. See for instance Eva Jakobsson, Industrialisering av älvar (Göteborg: Department of History, n°13, 1996); Arne Kaiser, “From Tile Stoves to Nuclear Plants – the History of Swedish Energy Systems,” in Semida Silveira (ed.). Building Sustainable Energy Systems - Swedish Experiences (Stockholm: Swedish National Energy Administration, 2001); Astrid Kander, Paolo Malanima and Paul Warde, Power to the People: Energy in Europe over the Last Five Centuries (Princeton: Princeton University Press, 2014) and Lars Lundgren, Energipolitik i Sverige 1890-1975 (Stockholm: Liber Förlag, 1978).

- 3. Nuno Luis Madureira, “The iron industry energy transition”, Energy Policy, vol. 50, November, 2012, 24-34.

- 4. Id.

- 5. Fredrik Olsson, Järnhanteringens dynamik. produktion, lokalisering och agglomerationer i Bergslagen och Mellansverige 1368-1910 (Umeå: Umeå University, 2007).

- 6. Lindmark & Olsson-Spjut, From organic to fossil and in-between (cf. note 1)

- 7. Karl-Gustav Hildebrand, Swedish Iron in the Seventeenth and Eighteenth Centuries: Export Industry Before the Industrialization (Stockholm: Jernkontorets Bergshistoriska Skriftserie 29, 1992).

- 8. Ibid.

- 9. Ibid., 11.

- 10. Peter King, “The Production and Consumption of Bar Iron in Early Modern England and Wales,” Economic History Review, vol. 58, n°1, 2005, 1-33.

- 11. Olsson, Järnhanteringens (cf. note 5).

- 12. Jan-Erik Pettersson, Från kris till kris. Den svenska stålindustrins omvandling under 1920- och 1970-talen [From slump to slump. The transformation of the Swedish steel industry during the 1920s and 1970s] (Stockholm: Department for economic history research at the Business School (EHF), 1988).

- 13. Nuno Luis Madureia, “The iron industry energy…” (cf. note 3).

- 14. Olsson, Järnhanteringens (cf. note 5).

- 15. Lindmark and Olsson Spjut, “From organic to fossil and in-between…” (cf. note 1)

- 16. Olsson, Järnhanteringens (cf. note 5).

- 17. Gunnar Arpi, Den svenska järnhanteringens träkolsförsörjning 1830–1950 [The charcoal consumption in the Swedish iron industry 1830–1950] (Stockholm: Jernkontorets Bergshistoriska Skriftserie 14, 1951).

- 18. Lindmark and Olsson-Spjut, “From organic to fossil and in-between…” (cf. note 1)

- 19. Johan Svidén, Industrialisering och förändrad miljöpåverkan: Råvaruflöden samt svavel- och kvicksilverutsläpp vidbruk i norra Kalmar län 1655–1920 [Industrialization and changing environmental impact: Flows of raw materials and sulphur and mercury emissions at iron plants in Northern Kalmar county 1655–1920] (Linköping: Linköping Studies in Arts and Science, 1996).

- 20. Svante Lindqvist, Technology on Trail. The Introduction of Steam Power Technology into Sweden, 1715-1736 (Uppsala: Uppsala Studies in History of Science, 1, 1984).

- 21. Eli Heckscher, Svenskt arbete och liv: Från medeltiden till nutid [Swedish work and life. From the Middel Ages to present] (Stockholm: Albert Bonniers förlag, 1941)

- 22. Hildebrand, Swedish iron in the seventeenth (cf. note 7)

- 23. Olsson, Järnhanteringens (cf. note 5).

- 24. Ibid.

- 25. Pettersson, Från kris till kris (cf note 12). See also Martin Fritz, Svenskt stål – Nittonhundratal – Från järnhantering till stålindustri (Södertälje: Jernkontorets Bergshistoriska Skriftserie, Nr. 33, 1997).

- 26. Lindmark and Olsson-Spjut, “From Organic to Fossil and in-between…”. Regarding imports coal and the Second World War, see also Sven-Olof Olsson, German Coal and Swedish Fuel, 1939-1945 (Göteborg: The Institute of Economic History, 36, 1975).

- 27. Ernst Söderlund ans Per-Erik Wretblad, Fagerstabrukens historia. Nittonhundratalet [The history of Fagersta iron works. The twentieth century], vol. 5 (Uppsala: Almqvist & Wiksell, 1957), 17-22.

- 28. Söderlund & Wretblad, Fagerstabrukens historia (cf. note 27), 50-52 and Fritz, Svenskt stål (cf. note 25).

- 29. Söderlund & Wretblad, Fagerstabrukens historia (cf. note 27), 52-65 and Fritz, Svenskt stål (cf. note 25).

- 30. Fritz, Svensk stål (cf. note 25), and Lars Magusson, Sveriges ekonomiska historia (Lund: Studentlitteratur, 2016), Pettersson, Från kris till kris (cf. note 25), Lennart Schön, En modern svensk ekonomisk historia: tillväxt och omvandling under två sekler (Lund: Studentlitteratur, 2014).

- 31. RA, Sakkunnige för viss utredning å järnhanteringens område, Kommittéer tillsatta av Kungl. Maj:t/regeringen, 1927, vol. 1.

- 32. Söderlund & Wretblad, Fagerstabrukens historia (cf. note 27), 52.

- 33. RA, Sakkunnige för viss utredning å järnhanteringens område, Kommittéer tillsatta av Kungl. Maj:t/regeringen, 1927, vol. 1.

- 34. RA, Sakkunnige för viss utredning å järnhanteringens område, Kommittéer tillsatta av Kungl. Maj:t/regeringen, 1927, vol. 5.

- 35. RA, Sakkunnige för viss utredning å järnhanteringens område, Kommittéer tillsatta av Kungl. Maj:t/regeringen, 1927, vol. 1.

Allen Robert C, “International competition in iron and steel, 1850–1913,” The Journal of Economic History, vol. 39, n°4, 1979, 911-937.

Allen Robert C, “Technology and the great divergence: Global economic development since 1820”, Explorations in Economic History, vol. 49, n°1, 1-16. https://doi.org/10.1016/j.eeh.2011.09.002

Andersson Lars Fredrik & Lindmark Magnus, “Is Structural Change Speeding Up? The Case of Sweden, 1850–2000”, Scandinavian Economic History Review, vol. 56, n° 3, 2008, 192-208. https://doi.org/10.1080/03585520802456941

Arpi Gunnar, Den svenska järnhanteringens träkolsförsörjning 1830–1950 [The charcoal consumption in the Swedish iron industry 1830–1950] (Stockholm: Jernkontorets Bergshistoriska Skriftserie 14, 1951).

Fritz Martin, Svenskt stål – Nittonhundratal – Från järnhantering till stålindustri (Södertälje: Jernkontorets Bergshistoriska Skriftserie, Nr. 33, 1997).

Heckscher Eli., Svenskt arbete och liv: Från medeltiden till nutid [Swedish work and life. From the Middel Ages to present] (Stockholm: Albert Bonniers förlag, 1941).

Hildebrand Karl-Gustaf, Swedish iron in the seventeenth and eighteenth centuries: Export industry before the industrialization (Stockholm: Jernkontorets Bergshistoriska Skriftserie 29, 1992).

Hildebrand Karl-Gustaf, Historik statistik för Sverige. Del 3, Utrikeshandel 1732-1970 (Stockholm: Statistiska centralbyrån, 1972).

Jakobsson Eva, Industrialiseringen av älvar. Studier kring svensk vattenkraftsutbyggnad 1900-1918 (Göteborg: Department of History, 1996).

Kaijser Arne, “From tile stoves to nuclear plants – the history of Swedish energy systems”, in Silvera S. (ed.), Building Sustainiable Energy Systems - Swedish Experiences (Stockholm: Swedish National Energy Administration, 2001).

Kander Astrid, “Economic growth, energy consumption and CO2 emissions in Sweden 1800-2000” (Ph.D thesis, Lund University, Department of Economic History, 2002).

Kander Astrid, Malanima Paolo, & Warde Paul, Power to the People: Energy in Europe over the Last Five Centuries (Princeton: Princeton University Press, 2014).

King Peter, “The production and consumption of bar iron in early modern England and Wales”, Economic History Review, vol. 68, no°1, 1-33.

Lindmark Magnus & Olsson-Spjut Fredrik, “From organic to fossil and in-between: new estimates of energy consumption in the Swedish manufacturing industry during 1800-1913” Scandinavian Economic History Review, vol. 66, n° 1, 18-33. https://doi.org/10.1080/03585522.2017.1401554

Lindqvist Sven, Technology on Trail. The introduction of steam power technology into Sweden, 1715-1736 (Uppsala: Uppsala Studies in History of Science, 1984).

Lungren Lars, Energipolitik i Sverige 1890-1975 (Stockholm: Liber Förlag, 1978).

Madureira Nuno Luis, “The iron industry energy transition”, Energy Policy, vol. 50, 24-34.

https://doi.org/10.1016/j.enpol.2012.03.003

Magnusson Lars, Sveriges ekonomiska historia (Lund:Studentlitteratur, 2016).

Olsson-Spjut Fredrik, Järnhanteringens dynamik : Produktion, lokalisering och agglomerationer i Bergslagen. Ekonomisk historia. Retrieved from http://www.diva-portal.org/smash/record.jsf?pid=diva2%3A140326&dswid=-1…

Olsson Sven-Olof, German Coal and Swedish Fuel, 1939-1945 (Göteborg: The Institute of Economic History, 36, 1975).

Pettersson Jan-Erik, Från kris till kris. Den svenska stålindustrins omvandling under 1920- och 1970-talen [From slump to slump. The transformation of the Swedish steel industry during the 1920s and 1970s] (Stockholm: Department for economic history research at the Business School (EHF), 1998).

Schön Lennart, En modern svensk ekonomisk historia: tillväxt och omvandling under två sekler (Lund: Studentlitteratur, 2014).

Svidén Johan, Industrialisering och förändrad miljöpåverkan: Råvaruflöden samt svavel- och kvicksilverutsläpp vidbruk i norra Kalmar län 1655–1920 [Industrialization and changing environmental impact: Flows of raw materials and sulphur and mercury emissions at iron plants in Northern Kalmar county 1655–1920] (Linköping: Linköping Studies in Arts and Science, 1996).

Söderlund Ernst & Wretblad Per Erik, Fagerstabrukens historia. Nittonhundratalet [The history of Fagersta iron works. The twentieth century], vol. 5 (Uppsala: Almqvist & Wiksell, 1957).